Our quantum materials research laboratories are equipped with state-of-the-art equipment for materials synthesis, structural characterization, electronic structure studies, and physical property measurements. These facilities are all located at the IAMM headquarters. Complementary research capabilities are offered through UT’s high-performance computing infrastructure, as well as ORNL’s supercomputing center and neutron sources such as HFIR and SNS.

Synthesis

Nearly all discoveries in materials research start with the synthesis of novel compounds. UT-IAMM houses one of the largest solid-state synthesis laboratories in the nation with a wide variety of furnaces for the synthesis of polycrystalline materials and large single crystals. Our motto: those who control the synthesis direct the future of materials science.

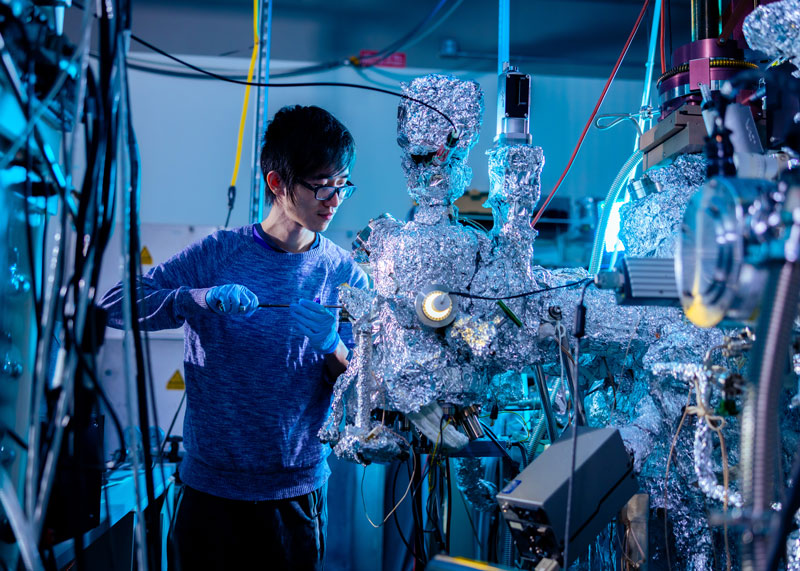

Epitaxial Synthesis

Molecular beam epitaxy is the most advanced thin film synthesis technique for the growth of single-crystalline thin films with the highest purity and atomically precise control of the thickness and composition. The quantum materials group employs MBE synthesis of transition metal oxides and chalcogenides as well as conventional group III-V semiconductors. It also employs pulsed laser deposition (or ‘laser MBE’) of complex oxide materials that are very difficult to grow via thermal MBE. The oxide MBE apparatus is an IAMM core facility.

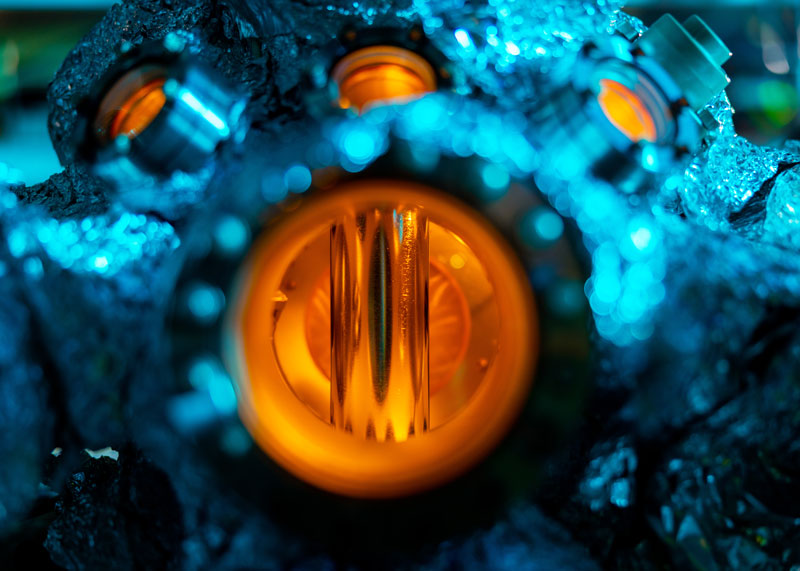

Electron Spectroscopy

The electronic properties of quantum materials are studied with various electron spectroscopies such as x-ray photoelectron spectroscopy (XPS), Auger electron spectroscopy, angle-resolved photoemission (ARPES) with time-resolution capability, and high-resolution electron energy loss spectroscopy (HREELS) in reflection mode. These techniques provide direct information on the electronic structure and excitations in quantum materials. The photoelectron spectrometers are part of an ultrahigh vacuum suite with added capabilities for molecular beam epitaxy and scanning tunneling microscopy.

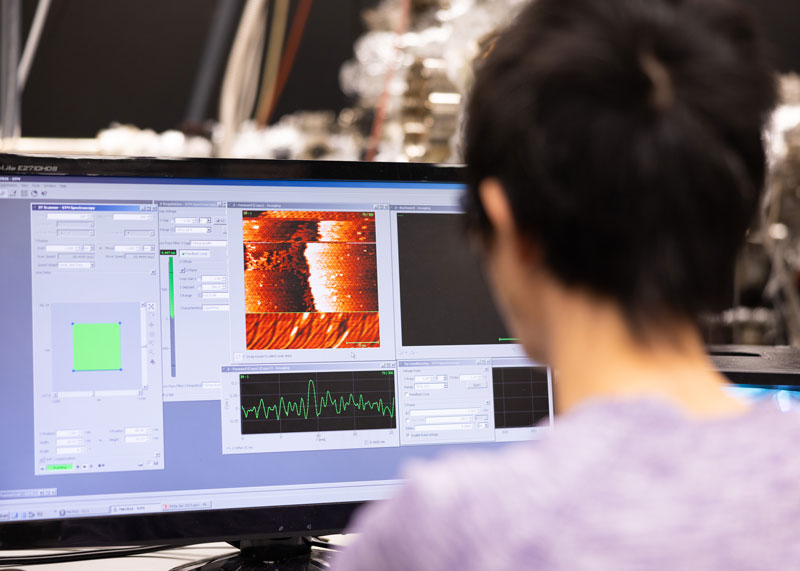

Topographic and Spectroscopic Surface Imaging

Scanning Tunneling Microscopy is a very powerful tool for studying the topography of a crystal surface or thin film with atomic resolution. In topographic imaging, one applies a small bias and measures a small quantum mechanical tunneling current between an atomically sharp metal tip and the crystal surface as a function of tip location above the surface. The latter can be controlled with Angstrom precision. It also is a spectroscopic tool that can measure the local electronic density of states (proportional to the dI/dV signal) as a function of applied bias and tip location. Differential conductance maps provide key information about, e.g., the Fermi surface of the material, presence of topological edge states, or symmetry of the order parameter in superconductors.

Electron Microscopy

IAMM’s Microscopy Core Facility houses a variety of scanning probe and electron microscopes, including an atomic force microscope (AFM) and a Nano-indenter, two transmission electron microscopes, a scanning electron microscope and two Dual Beam Focused Ion Beam (FIB) instruments. One showcase instrument is the 300 keV ThermoFischer monochromated and aberration corrected TEM/STEM with spatial resolution down to 40 pm, allowing atomic resolution EDS and EELS. Another showpiece is a Plasma FIB providing ion beams of Xe, Ar, N, and O, for imaging and processing of prototypical devices. This instrument is equipped with EDS and EBSD for microstructural and chemical analysis.

Structural Characterization

Characterization of new materials usually starts with structure determination via x-ray diffraction. IAMM’s Diffraction core facility houses a variety of x-ray diffractometers. Basic usage of these machines revolves around the identification and quantification of crystalline phases, space group symmetry and lattice parameters, crystallite size, and micro strain. More advanced uses include high-temperature in-situ experiments, investigating preferred orientation with pole figures, determining residual stresses, and studying thin films with X-ray reflectivity, among others.

Electrical and Magnetic Property Measurement

Quantum materials exhibit a wealth of fascinating electrical and magnetic properties. These can be measured using our Quantum Design Physical Properties Measurement Systems (PPMS) and MPMS-VSM magnetometer system. We routinely access temperatures as low as 2 Kelvin and magnetic fields up to 14 Tesla. The magnetometer is equipped with a Helium-3 option for magnetization measurements down to 0.4 Kelvin.

Research at low temperatures

Many experiments are done at low temperatures and require liquid helium cooling, which is an increasingly rare and expensive commodity. To reduce the cost of low-temperature experiments, our researchers have access to a central helium recovery and liquefaction facility capable of producing 60 liters of liquid helium per day. The system is equipped with a 500-liter storage dewar.

Neutron Scattering

Neutron scattering is a powerful way to probe the magnetism and therefore quantum behavior in materials. We principally use the Spallation Neutron Source and High Flux Isotope Reactor, two of the World’s premier neutron facilities located at Oak Ridge National Laboratory for our experiments. We both undertake experiments on the structure and dynamics of materials as well as push scientific boundaries by developing new techniques and sample environments. Much of our work utilizes the Shull Wollan Center, the UT Center for neutron science on the Oak Ridge National Laboratory campus.

High-Performance Computing

The Infrastructure for Scientific Applications and Advanced Computing (ISAAC) at UT offers both secure and non-secure enclaves containing 1000s of advanced computer cores and multi-GPU nodes integrated with a high-speed Lustre file system with petabyte scale storage capacity. ISAAC is connected to the larger US academic internet through Internet2 connectivity. We also use the OLCF supercomputing resources at ORNL which include the exascale Frontier supercomputer, the current World number 1, as well as other national facilities.

Combinatorial Thin Film Sputtering

Combinatorial thin film sputtering is a versatile technique that allows for high throughput screening for rapid materials discovery. The team leverages combinatorial thin films to survey very large phase spaces for both compositionally complex alloys and ceramics (oxides, nitrides and carbides). Our system is comprised of four sputtering sources that can be deposited simultaneously at both elevated temperature and with substrate bias. Additionally, a sputtering model has been developed so optimum sputtering parameters can be arrived at quickly to cover the desired composition space.

High Temperature Formation and Processing (UT)

High temperature furnaces (1700ᵒC), both atmosphere/vacuum controlled

- High-quality high-temperature furnaces that can reach temperatures up to about 1700°C (~3092°F). Available furnaces are easy-to-use and have programmable controllers which allow for precise temperature and process control, resulting in high temperature heating with excellent conformity and consistency.

Uniaxial hot press (up to 2000°C & 25 ton), atmosphere/vacuum controlled

- A critical tool used for the high-temperature and high-pressure consolidation of materials. It is primarily employed in the processing of materials such as metals, ceramics, and composites, where achieving uniform density and minimizing porosity is crucial. The isostatic hot press applies pressure uniformly from all directions, ensuring even distribution of force on the material being processed. This uniform application of pressure helps in eliminating internal voids and imperfections, resulting in materials with enhanced mechanical properties and improved structural integrity, which are beneficial for applications under extreme environment conditions.

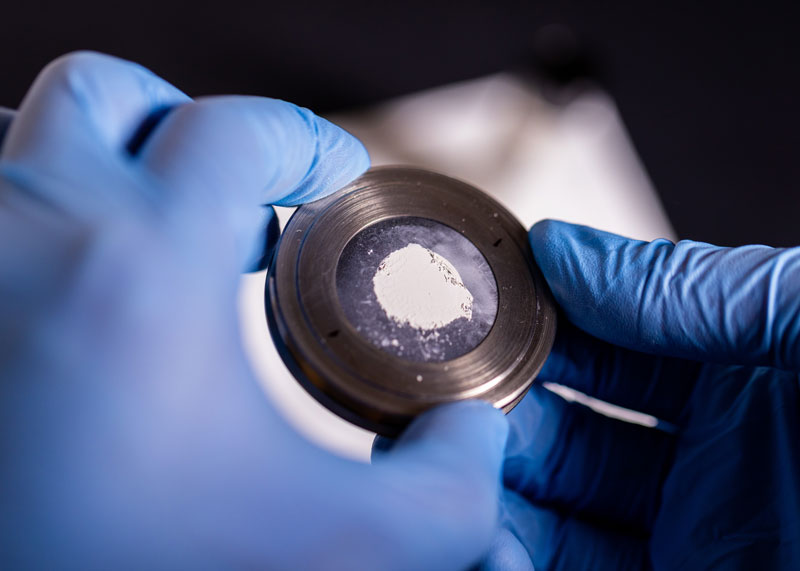

Spark Plasma Sintering (SPS)

- An innovative powder metallurgy technique used for the consolidation and densification of materials such as metals, ceramics, and composites from powders. It operates on the principle of applying both pressure and pulsed direct current (DC) to the powder compact simultaneously, enabling the rapid consolidation of materials at lower temperatures and shorter processing times compared to conventional sintering methods. The simultaneous application of pressure helps in achieving high-density compacts with improved mechanical properties, such as enhanced strength, hardness, and wear resistance.

High Temperature Formation and Processing (ORNL)

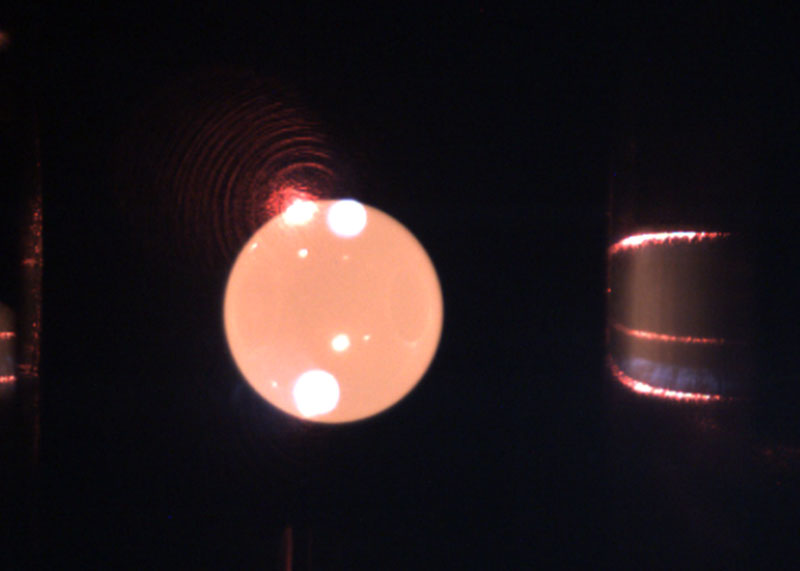

Levitation Devices

- Container-less laser heating/quenching (2500°C and up, atmosphere controlled) for off-line physical property measurements and in situ scattering studies

- Aerodynamic levitation: oxides up to 3000°C with rapid laser heating/cooling (Ar and Ar/O2 mixtures)

- Electrostatic levitation: metals up to 3000°C under high vacuum (~10-7 torr)

- Melting points, phase transitions, thermal expansion, density, viscosity, surface tension, resistivity, crystallization velocity, vapor pressure….

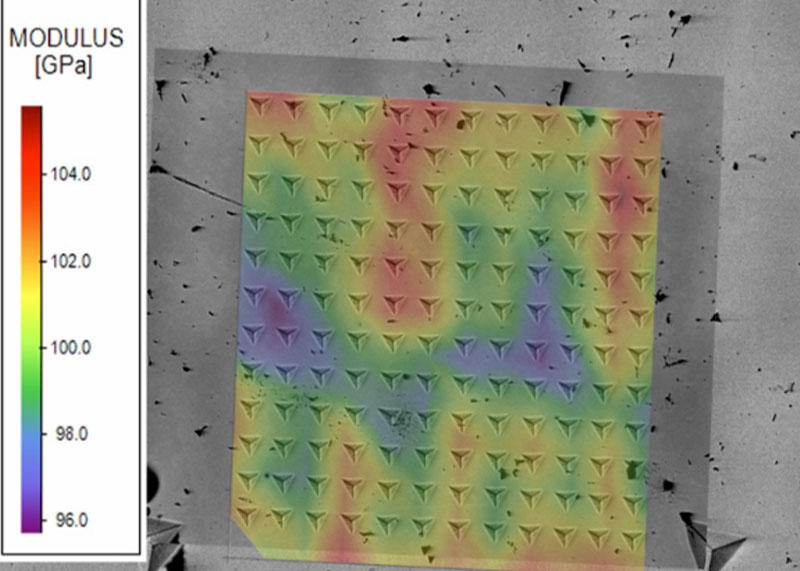

Multi-scale Mechanical-Property Characterization

Offering nanoindentation based structure-property relation characterization techniques. Nanoindentation is used to determine mechanical properties of interest such as hardness and modulus of materials. The variety of nanoindentation and micro hardness testing machines allow probing materials at different length scales. A Nanoflip system is available for in SEM operation allowing combined indentation and imaging. The iMicro is capable of performing a large number of automated indents in varying modes depending on user requirements. The LECO machine is a versatile microhardness measurement tool capable of mapping hardness of large samples with automated imaging for rapid data analysis. Additionally, laser and optical table-top microscopes are utilized to characterize surface roughness and indentation profiles. In addition, extensive thermo mechanical characterization tools exist for meso to macro scale including high temperature (1,500˚C and above) DSC, TGA, DMA and bulk servohydraulic testing systems with environmental chambers for axial and combined multi-axial loading including torsional shear.

Ion Beam Materials Laboratory (TIBML)

The Tennessee Ion Beam Materials Laboratory (TIBML) is a UTK core user facility available locally to the University of Tennessee community, as well as any domestic or international collaborative research institute. The TIBML is currently equipped with a 3 MV tandem accelerator, a 30 kV e-gun, two ion sources, three beamlines, and four end stations that provide state-of-the-art capabilities for ion beam analysis, ion beam materials modification, fundamental research on ion-solid interactions, and applied research on radiation effects in materials for both terrestrial and space radiation applications. Upcoming milestones and capabilities include a new 200 kV Scanning Transmission Electron Microscope (STEM), a 300 kV ion implanter, a dedicated low energy beamline, and two new low energy ion sources.

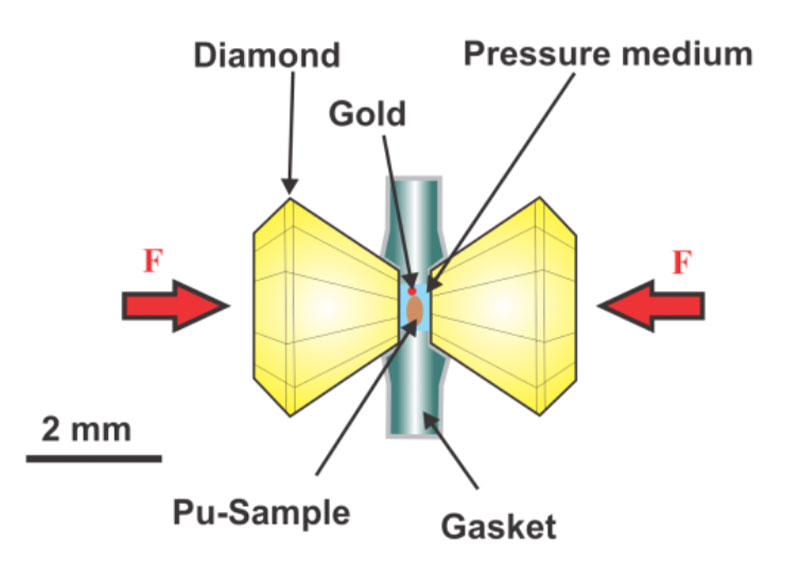

Diamond Anvil Cells (DACs)

Static high-pressure experiments can be performed using diamond anvil cells (DACs). Pressures of up to a few hundred GPa can be reached. Besides conventional high-pressure cells, rotational and dynamic DACs can be utilized to study how shear and fast compression and decompression affect the material response. In a rotational DAC, one diamond anvil can be rotated with respect to the other over a range of angles, which exerts well-controlled shear to the sample. In a dynamic DAC, both anvils are driven by a piezo system that allows extremely fast compression rates up to TPa/sec. High temperatures can be simultaneously coupled with pressure experiments to probe a wide range of high P-T conditions using resistive or laser heating, reaching a few hundred to several thousand Kelvin. DACs can be used for in situ measurements of equations of states, melting curves, and phase transformation kinetics under well-controlled extreme conditions. They can also be used for synthesis of materials far from equilibrium with novel properties and improved material durability.